Introduction:

In any Industrial Machinery elements like Shafts, Keys-Couplings, Levers, Cams, Screws, Belts-Pulleys, Gears, Chain-Rope drives, Springs are the parts which drive and convert forces to achieve the purpose of the equipment apart from the machine skeleton structures and enclosures.

Definition of Springs:

Springs are the elastic bodies which will deflect when loaded and to recover its original position / shape after the given load is removed.

Here, we look in to its Applications, Types, Materials used and Helical Compression Spring’s Design parameters

Typical Applications:

- Transportation – Auto/Locomotives, Aerospace E.g. – Shock observers, Vibration dampers, Landing gears, Railway buffers, Engines valves, Governors, Clutches etc..

- Medical devices – E.g. Peripheral patient handling devices, Reliability testing systems

- Industrial – Includes all machineries Eg. Drive tensioners, Material handlers, Robotics, Damping and Isolation mechanisms etc…

- FMCG – Home appliances, Entertainment equipment, Toys

Eg. Mix-grinder spring loader, Devices On/Off push buttons, Toys energy storing springs etc..

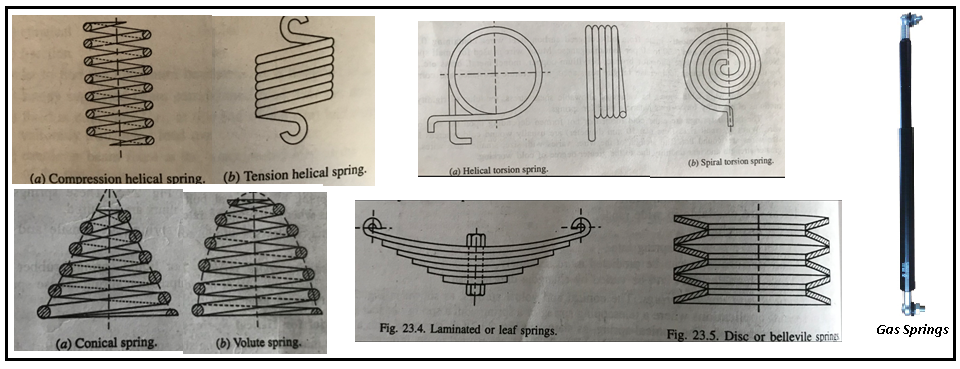

Types of Springs (Refer to Picture):

Springs are majorly classified based on its Geometry irrespective of other parameters like application,

materials and other considerations

Helical springs – Compression, Tension in the form of Conical / Volute shapes

- Torsion springs – in the form of Helical torsion, Spiral torsion

- Leaf springs

- Disc / Belleville springs

- Special springs (Gas springs, Rubber springs, Ring Springs, Machined Springs)

Spring materials:

The materials to be used for springs demands the following essential characteristics such as,

High fatigue strength, Ductility, Resilience, Creep Resistant-

Considering these properties and application service factor requirement following materials are being selected with stated Heat treatments (Oil tempered)

- Carbon (0.6 to 1.0%) Steel wire

- Music Wire

- Oil tempered wire

- Hard-drawn spring wire

- Stainless steel wire

- Monel metal

- Phosphor bronze

- Brass

Important Design Parameters, Formulae, and its metric units for Helical Compression Springs:

Sunstream’s product engineering team is experienced in using different type of spring technology to manage, transfer and change the force in the equipment. Sunstream’s mechanical design team is well experienced in 3D modeling services, analysis and detail engineering to get the needed result in equipments using components like springs, coupling, levers and gears.

+1.585.935.7123

+1.585.935.7123 +91-804-148-6861

+91-804-148-6861