API 650 and API 620 are both standards developed by the American Petroleum Institute (API) for the design and construction of storage tanks, but they differ in several ways:

In generic, API 650 covers the design, fabrication, erection, and inspection of atmospheric storage tanks (tanks that operate at ambient pressure) whereas API 620 applies to the design and construction of low-pressure storage tanks (tanks that operate at pressures up to 15 psi or 103 kPa).

-

Pressure Levels:

API 650 tanks are designed for tanks with internal pressures not exceeding 2.5 psi (17 kPa), while API 620 tanks can handle higher pressures up to 15 psi (103 kPa). This difference allows API 620 tanks to store liquids that require slightly higher-pressure containment.

-

Design Requirements:

API 650 tanks have specific requirements for the thickness, material, welding, and inspection of the tank shell, bottom, and roof. API 620 tanks have similar requirements but are more stringent due to the higher-pressure capabilities, requiring additional design considerations such as more extensive testing and analysis.

-

Tank Shape:

API 650 tanks are typically cylindrical in shape, while API 620 tanks can be designed as cylindrical or rectangular.

-

Applications:

API 650 tanks are commonly used for storing petroleum and petrochemical liquids, while API 620 tanks are suitable for a wider range of liquids, including liquefied natural gas (LNG) and other cryogenic liquids.

In summary, API 650 tanks are for atmospheric storage with lower pressure requirements, while API 620 tanks are for low-pressure storage with higher pressure capabilities, including cryogenic liquids.

Applications of API 650 tank and API 620 tank

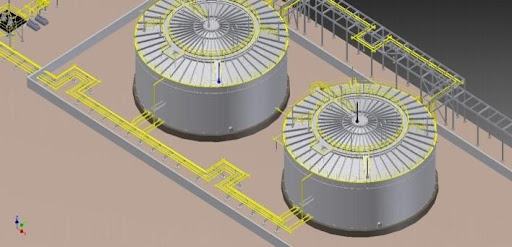

API 650 tanks are commonly used for the storage of petroleum and petrochemical liquids. Some specific applications are as follows:

- Crude oil storage: API 650 tanks are frequently used for the storage of crude oil in refineries, terminals, and production facilities.

- Refined product storage: These tanks are suitable for storing various refined petroleum products such as gasoline, diesel, jet fuel, and heating oil.

- Chemical storage: API 650 tanks are also utilized for storing a wide range of chemicals, including acids, solvents, and other liquid chemical products.

- Water storage: These tanks can be employed for the storage of water in various industrial, commercial, and municipal applications.

API 620 tanks are designed for low-pressure storage and some specific applications are as follows:

- Liquefied Natural Gas (LNG) storage: API 620 tanks are commonly used for the storage of LNG, which requires cryogenic temperatures and specialized containment.

- Cryogenic liquid storage: These tanks are suitable for storing other cryogenic liquids, such as liquid nitrogen, liquid oxygen, and liquefied ethylene.

- Ammonia storage: API 620 tanks can be utilized for the storage of ammonia, which is used in various industries, including agriculture, refrigeration, and chemical manufacturing.

- Propane and butane storage: These tanks can also be used for the storage of liquefied gases, such as propane and butane, commonly used for heating, cooking, and as fuel for vehicles.

API 650 tanks are typically used for petroleum, petrochemicals, chemicals, and water storage, whereas API 620 tanks are suitable for cryogenic and low-pressure storage of substances like LNG, ammonia, and liquefied gases.

Sunstream is a leading provider of mechanical engineering services. Our offerings in the area of mechanical design, CAD drawing services, 3D modeling, Tank calculations and FEA analysis assist our customers to complete their projects faster and at a reduced cost. Please reach out to us to know more about our API Tank Design, Pressure vessel design and heat exchanger design services.

+1.585.935.7123

+1.585.935.7123 +91-804-148-6861

+91-804-148-6861